Opentools

The rapid proliferation of digital fabrication tools, combined with the collaborative power of the web has led to a new era of design and making. As the barrier to entry traditionally imposed on design and making is reduced they become more accessible. It signifies the fall of the professional and the rise of the amateur.

The digitisation of design through CAD has given way to a sharing and distribution movement much like that seen in software. Designs can be shared as software, before being downloaded and made using digital fabrication tools. As this happens, principles derived from the Free Software Foundation and Open Source initiative are transitioning into design, disrupting accepted conventions, giving rise to community orientated design systems.

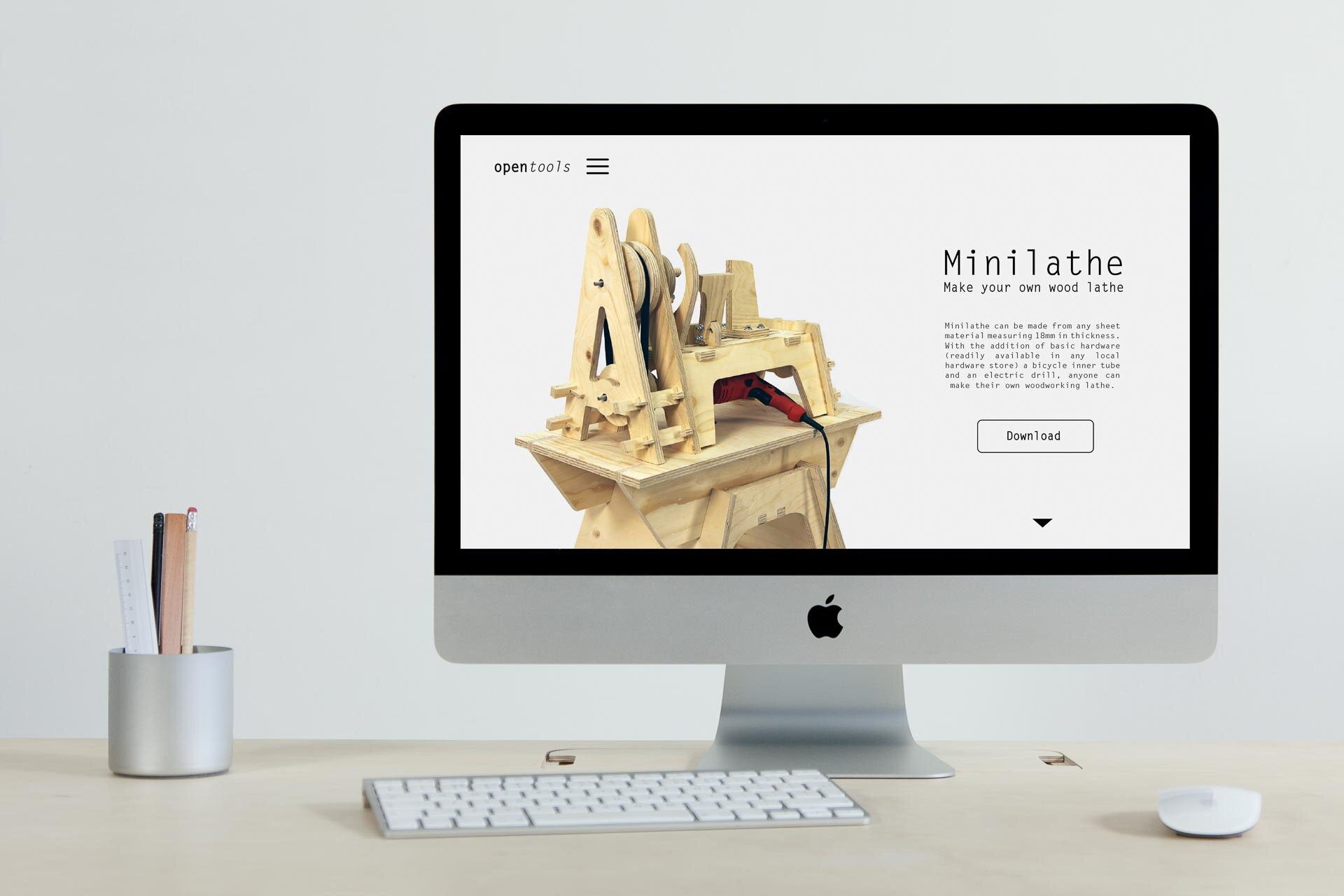

Opentools is a web-platform for the sharing of making tools, mechanisms, and contraptions. Anyone can publish their “Opentool” with file downloads, instruction guides, photos, and videos. All hosted ‘tools’ are designed to be manufactured via CNC milling (the cutting of sheet material by a computer controlled drill) or 3D printing processes. Such machines are common across FabLabs, TechShops, and other independent maker spaces, allowing members total freedom to produce anything found on the Opentools platform.

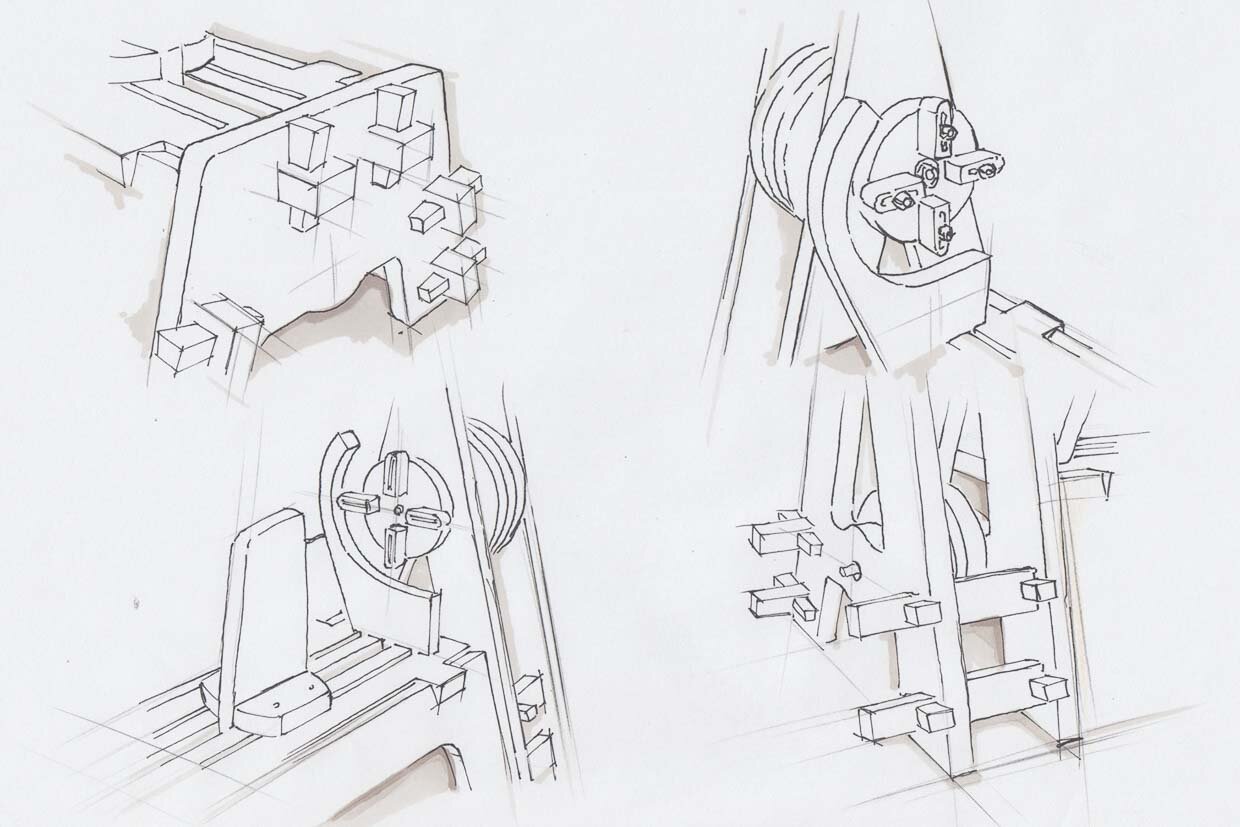

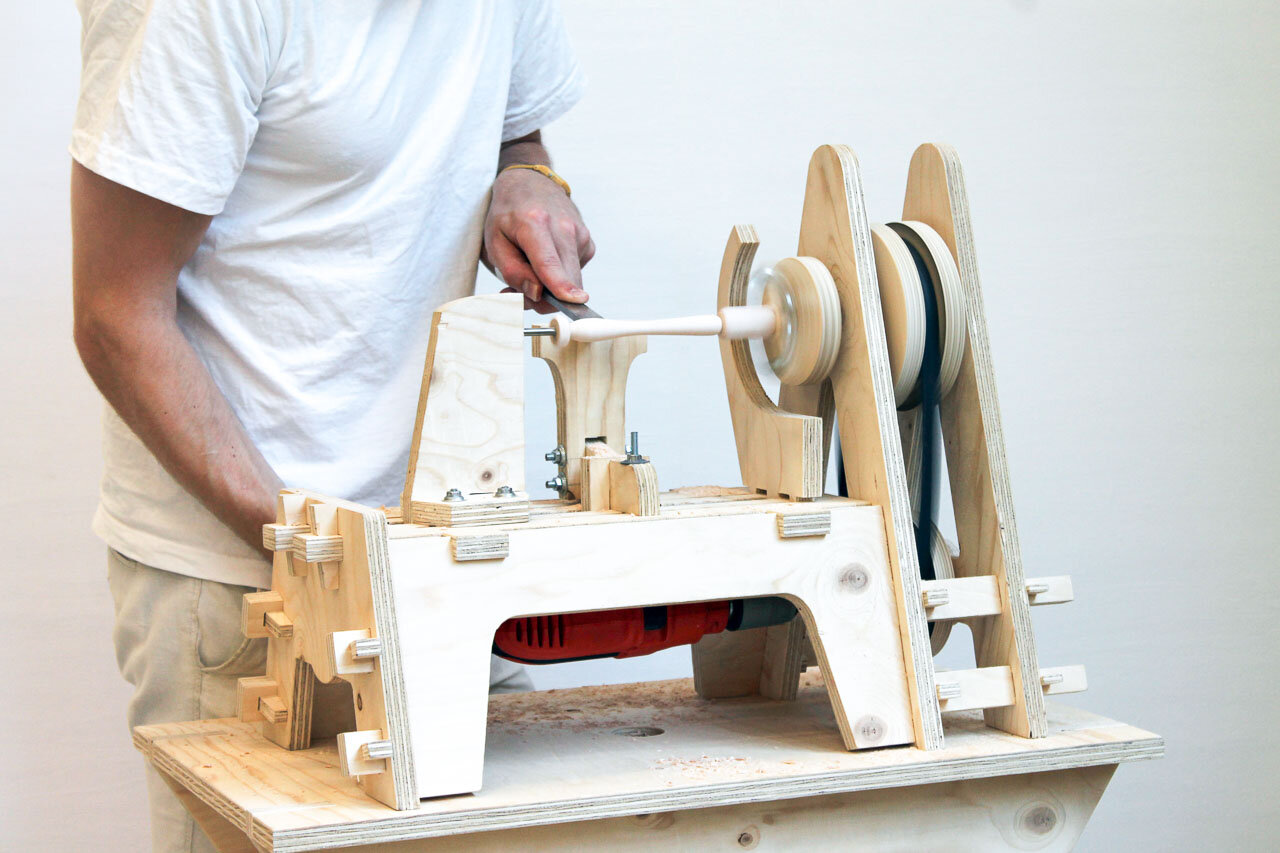

The first Open Source ‘tools’ to be hosted included a CNC made wood lathe (pictured), workbench (pictured), disc sander and potters wheel.

Minilathe can be made from any sheet material measuring 18mm in thickness. With the addition of basic hardware (readily available in any local hardware store) a bicycle inner tube and an electric drill, anyone can make their own woodworking lathe.